Coil Upenders Product Overview

Welcome to our comprehensive product page for Coil Upenders, the essential equipment for safe and efficient handling of heavy coil materials. Our Coil Upenders are engineered to streamline the process of turning coils to the desired orientation, whether for storage, processing, or shipping.

Key Features

Robust Construction

- Built with high-grade steel for maximum durability.

- Designed to withstand the rigors of industrial environments.

High Load Capacity

- Capable of handling a wide range of coil weights and sizes.

- Engineered to provide stable support for heavy-duty operations.

Versatility

- Accommodates various types of coils, including steel, aluminum, copper, and more.

- Suitable for use in metalworking, automotive, and manufacturing industries.

Safe and Efficient Operation

- Equipped with safety features to protect operators.

- Ergonomic controls for ease of use and operator comfort.

Precision Control

- Smooth and precise turning of coils with adjustable speed settings.

- Ensures accurate positioning of coils for further processing or storage.

Product Options

Manual Coil Upenders

- Cost-effective solutions for low-volume or light-weight coils.

- Operator-controlled movement for hands-on management.

Motorized Coil Upenders

- Ideal for high-volume or heavy-weight coil operations.

- Automated turning with remote or panel controls for enhanced efficiency.

Hydraulic Coil Upenders

- Offers powerful performance for the most demanding tasks.

- Hydraulic systems provide controlled and steady coil inversion.

Customization

- Tailored designs to meet specific industry requirements.

- Custom load capacities and sizes available upon request.

Safety Features

- Emergency stop functions for immediate halting of operations.

- Protective guards and barriers to prevent accidents.

Technical Support

- Comprehensive after-sales service and support.

- Maintenance and repair services to ensure long-term reliability.

Contact Us

For more information on our Coil Upenders, or to request a quote or a demo, please contact our sales team. We are dedicated to providing you with the best solution to meet your coil handling needs.

PVC管材缠绕包装线

PVC管材缠绕包装线是单管,多管管材包装解决方案的机器。 风鼎机械管道包装系统是应我们的客户长久要求而设计制造的,正是这种要求和反馈促成了管道包装系统的发展和不断进步。 管袋包装机主要用于包装单体塑料管材,pvc管材,棒材,铜管材,型材……该设备可以使管材自动装袋。 (参考视频) 选用我们风鼎机械自动设备,你得到的不只是好的质量,可靠的产品,我们还将提供终身的维修服务。 如何修复包装流水线设备 在社会快速发展的今天,自动化包装流水线设备给我们带来了巨大的经济效益,但是随着设备的长期使用,必然会带来一定的磨损,如何修复包装流水线设备呢,具体方法如下: 根据自动化包装流水线在维修工作中常用的修复技术按其所采用的工艺大体分为机械修复法、焊接修复法、电镀修复法、喷涂修复法及粘接修复法等,具体选择时应考虑以下几方面的因素 1.修复二艺对零件精度的影响,如果被修复零件要预热或修复过程中温度较高,会使零件退火,淬火组织遭破坏,热变形增大,故修复后要加工整形,热处理等,因此对精度有要求的零件,修复时要考虑其变形。 2.零件修复后的强度各种工艺在一般条件下所能达到的修补层强度相差很大,因此修补层的强度、修补层与零件的结合强度以及零件修复后的强度变化情况是修理质量的重要指标。 3.修复工艺对零件材质的适应性,在现有修复工艺中,有的材料合适修复,有的则是对零件有毁灭性打击,各种工艺对材料的适应有很大的局限性,因此要选对材料。 4.各种修复工艺能达到的修补程度 ,要根据零件的磨损程度来选择不同的修复工艺,不同工艺所能达到的修复层厚度各不相同。…

旋转臂托盘包装机

风鼎机械:摇臂式包装机 在过去的20年中,Fuffy包装系统已经成为世界领先的拉伸包装系统制造商之一,包括拉伸膜的机理和应用。这些系统应用于瓦楞纸箱行业,以帮助组织和保护瓦楞纸板在粉尘和损坏、运输和储存处理中的负荷。我们生产各种类型和尺寸的拉伸膜,适用于自动半自动和全自动拉伸包装系统。我们的销售,设备服务,客户服务和工程部门可以帮助您设计质量保护包装系统为您的行业。旋转臂拉伸包装是一种托盘包装机类别,区分现有的机械臂和“转弯”托盘包装。这种类型的生产率与中级水平相比,具有旋转腭(平均生产率较低)和旋转环(平均生产率较高)。旋转臂拉伸包装机为需要重包装或非常轻盈的客户提供了新的解决方案。不稳定负载,其中一台电机和旋转平台可能不够 在过去的20年里,Fuffy包装系统已经成为世界领先的拉伸包装系统制造商之一,包括拉伸膜的机理和应用。这些系统应用于瓦楞纸箱行业,以帮助组织和保护瓦楞纸板在粉尘和损坏、运输和储存处理中的负荷。我们生产各种类型和尺寸的拉伸膜,适用于自动半自动和全自动拉伸包装系统。我们的销售,设备服务,客户服务和工程部门可以帮助您设计质量保护包装系统。 旋转臂拉伸包装是一种托盘包装机类别,区分现有的机械臂和“转弯”托盘包装。这种类型的生产率与中级水平相比,具有旋转腭(平均生产率较低)和旋转环(平均生产率较高)。旋转臂拉伸包装机为需要重包装或非常轻盈的客户提供了新的解决方案。 更多自动化包装尽在:icoiler.com,fhopepack.com—风鼎机械

pallet inverter manufacturer in China

This pallet inverter drived by hydraulic system for exchaging the pallet load. The operation…

Envolvedora de bobinas automática

La línea de empaque de bobina automática, Envolvedora de bobinas automática se puede utilizar para empaquetar…

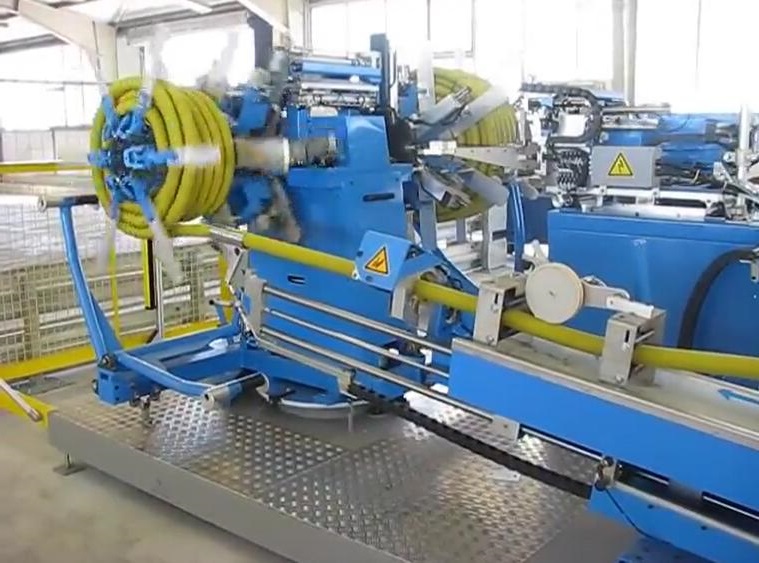

Automatic coiler for pipe

Thanks for your feedback about automatic coiler. Firstly, about your doubts, response as followings: 1….

a) do you have tube samples to test the coiling machine? I mean ;…

Automatic pipe coiler

Wish you a great day. Glad to hear your nice feedback. About your doubts, response…

automatic coilers

Thank you for your answers. Yes the direction of the conveyor is good either at…