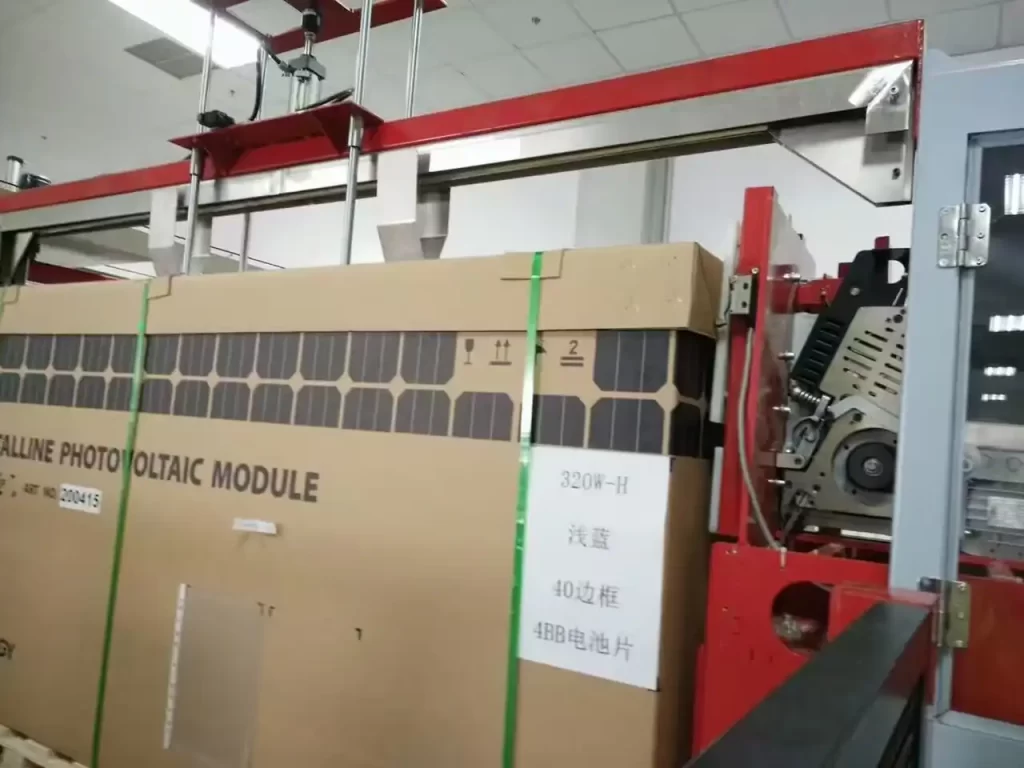

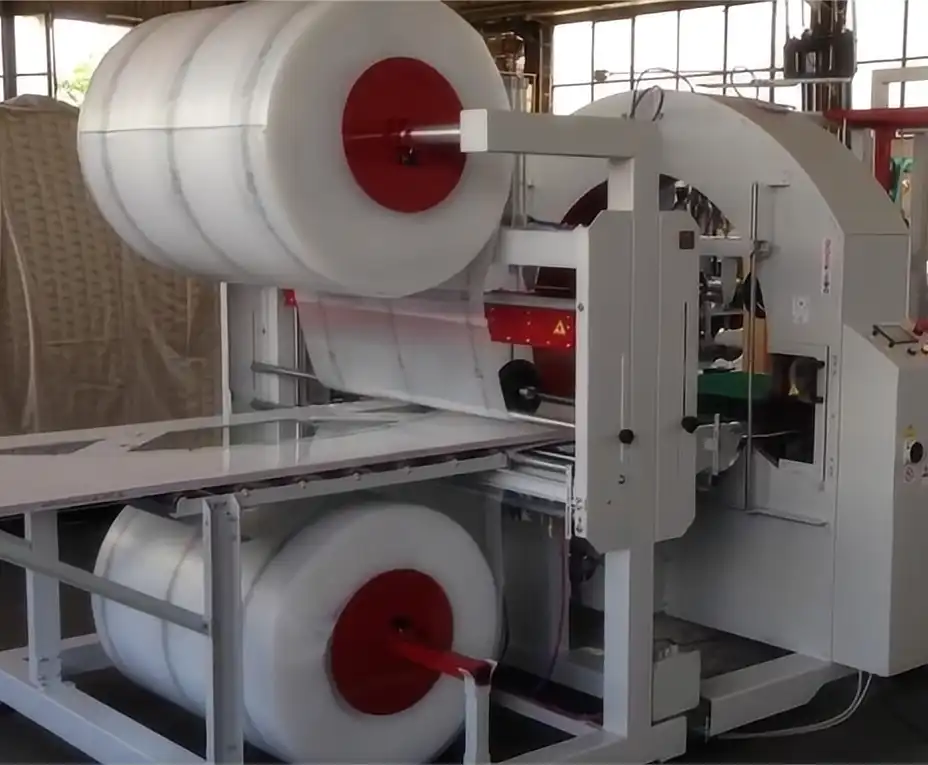

Horizontal Wrapping

Efficient horizontal stretch wrapping machines for various straight objects to streamline your packing process

Flexible Customization

Tailored packaging solutions that suit your specific requirements for effective protection and presentation

High Productivity

Innovative packaging equipment for large products, furniture, doors, and windows, enhancing productivity at reduced costs

Exceptional quality and service, their orbital wrappers exceeded our expectations.