Coil Upenders Product Overview

Welcome to our comprehensive product page for Coil Upenders, the essential equipment for safe and efficient handling of heavy coil materials. Our Coil Upenders are engineered to streamline the process of turning coils to the desired orientation, whether for storage, processing, or shipping.

Key Features

Robust Construction

- Built with high-grade steel for maximum durability.

- Designed to withstand the rigors of industrial environments.

High Load Capacity

- Capable of handling a wide range of coil weights and sizes.

- Engineered to provide stable support for heavy-duty operations.

Versatility

- Accommodates various types of coils, including steel, aluminum, copper, and more.

- Suitable for use in metalworking, automotive, and manufacturing industries.

Safe and Efficient Operation

- Equipped with safety features to protect operators.

- Ergonomic controls for ease of use and operator comfort.

Precision Control

- Smooth and precise turning of coils with adjustable speed settings.

- Ensures accurate positioning of coils for further processing or storage.

Product Options

Manual Coil Upenders

- Cost-effective solutions for low-volume or light-weight coils.

- Operator-controlled movement for hands-on management.

Motorized Coil Upenders

- Ideal for high-volume or heavy-weight coil operations.

- Automated turning with remote or panel controls for enhanced efficiency.

Hydraulic Coil Upenders

- Offers powerful performance for the most demanding tasks.

- Hydraulic systems provide controlled and steady coil inversion.

Customization

- Tailored designs to meet specific industry requirements.

- Custom load capacities and sizes available upon request.

Safety Features

- Emergency stop functions for immediate halting of operations.

- Protective guards and barriers to prevent accidents.

Technical Support

- Comprehensive after-sales service and support.

- Maintenance and repair services to ensure long-term reliability.

Contact Us

For more information on our Coil Upenders, or to request a quote or a demo, please contact our sales team. We are dedicated to providing you with the best solution to meet your coil handling needs.

Following is the main solution for the pipe packaging that aviable for different pipe and…

linha de embalagem de bobina automática

Fhope fornecendo várias linhas de embalagem de bobinas para se juntar à linha de corte…

WIRE COIL PACKING MACHINE WITH GOOD PRICE

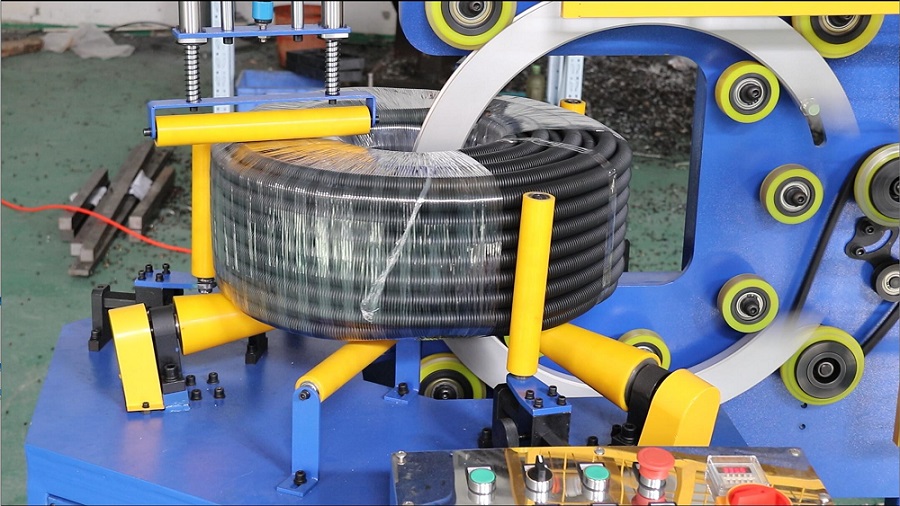

The wire coil packing machine for improving the packing procession with higher automation level. wrapping…

automatic cable coiling and strapping machine

automatic cable coiling and strapping machine The packing line is able calculating the cable…

volteadora manual de palet | Máquina volteador de palets

https://youtu.be/neTi6OPdfS0 More information: https://www.fhopepack.com volteadora manual de palet El equipo está compuesto por una plataforma móvil…

Rotating arm tray packaging machine

More information: https://www.fhopepack.com In the past 20 years, Fhope packaging system has become one of…

Automatic tray stretch film winding packaging machine

More information: https://www.fhopepack.com The rotating arm packing machine is used to pack the stretch film…

深筒包装机-钢卷包装——风鼎机械

深筒缠绕包装机是针对大型钢卷、铝卷、铜卷、盘圆等宽幅的物体进行穿心缠绕而包装设计的大型包装机。 风鼎机械提供专业定制的深筒包装机,为您和您的产品极大及长久的减少人力物力损耗付出, 提供了优秀的包装效果及包装效率。 分析包装生产流水线设备故障原因 开展自动化包装流水线故障原因分析时,要结合本企业拥有的自动化包装流水线设备种类和故障管理的实际需要。将本企业的故障原因种类规范化,明确每种故障所包含的内容。根据划分的故障原因种类,容易看出每种故障的主要原因或存在的问题当设备发生故障后进行鉴定时,对故障原因种类的划分应有统一的原则,要按同一规定确定故障的原因(种类)。当每种故障所包含的内容已有明确规定时,便不难根据故障原因的统计资料发现本企业包装生产流水线产生设备故障的主要原因或问题。 以下是故障原因的分类: 1设计制造问题,原设计结构、尺寸、配合、材料选择不合理等,原制造的机加工、铸锻、热处理、装配、标准元器件等存在问题 。 2安装使用问题,基础、垫铁、地脚螺栓、水平度、防振等问题 ,具体使用的问题,操作保养不良,不清洁,调整不当,未及时清洗换油,操作不当等 。超负荷,使用不合理 ,加工件超规格,加工件不符合要求,超切削规范,加工件超重,设备超负荷等 。 3润滑不良,不及时润滑,油质不合格,油量不足或超量,油的牌号种类错误;加油点堵塞,自动润滑系统工作不正常等 。 4修理质量问题,修理、调整、装配不合格.备件、配件不合格,局部改进不合理等 。 5人为因素,操作者马虎大意,由于操作者工作时精神不集中引起的故障 ,操作者技术不熟练,一般指刚开始操作一种新设备,或工人的技术等级偏低 ,违章操作,有意不按规章操作。 6自然磨损劣化,正常磨损、老化等。…